Gilding is a truly ancient process, believed to have been first developed in Turkey over 8,000 years ago. The ancient Egyptians used it embellish the sarcophagi of pharaohs, the Phoenicians used it to plate less expensive metals to sell them for more at market, and more recently Europeans have used gilding to cover surfaces ranging from ceilings, wood frames, to dinnerware. While many of the processes to apply gold leaf are rooted in similar principles, the process has evolved greatly with time—which has made the process safe and ensures that the finish lasts longer. When it comes to writing a specification, it is important to do a pre-project investigation to understand not only the scale of the needed gilding restoration, but also understand what are the underlying issues causing the gold leaf finish to fail. Is the project indoors or outdoors? What is the base material to which the gold leaf was applied? How was the gold bonded to the surface? Is that the most effective method? Developing a baseline understanding of these key questions will ensure your conversations with prospective restoration professionals remains grounded. Additionally, we encourage prospective clients to do the following four things prior to starting any gold leaf project or specification:

1. Understand the Gilding Process

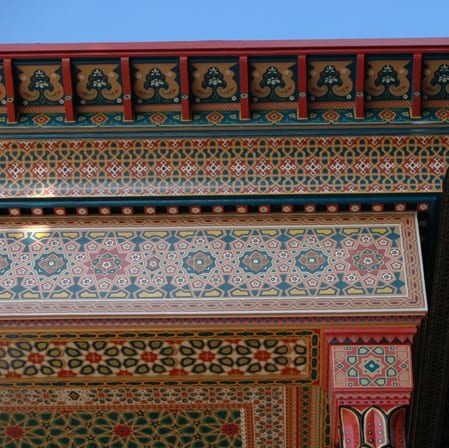

Application methods change based on the material the gold leaf is being applied. These are a few of the most common types of gilding applications:

Mechanical Gilding

- Overlaying: this is the simplest form of gilding and is most likely the original form used in ancient times—references to this type are made in both Greek mythology and the Bible. Heated gold is hammered into thin sheets and then applied once cooled to the intended surface; note that the layer of gold associated with this process is significantly thicker than golf leaf which, was not invented until the Middle Ages. A layer of adhesive is applied to prepare the surface—most commonly it is a simple adhesive made from vegetation and/or animal bones. In ancient times, bitumen (asphalt) was commonly used as the adhesive.

- Water gilding: enables the gold finish to be mirror-like and polished in appearance. This process uses ground gypsum/chalk mixed with glue as a base coat. The surface is dampened and then buffed again with water.

- Oil-gilding: similar to water gilding, however, the surface is buffed with an oil to finish—typically linseed oil.

Chemical Gilding

- Cold Gilding and wet gilding are process used to apply gold to metal surfaces; the former to sterling silver (vermeil finish) and the latter to more generalized metals.

2. Determine the Scope

How large is the project at hand? Are there confounding variables, like active water damage that if unresolved could damage the restored surface? It is important to know as many variables as possible, prior to consulting experts. By thoroughly reviewing the scope of the proposed restoration, you will be able to get a feel for not only what you are trying to achieve with the restoration, but also the kinds of experts are needed to help you accomplish it.

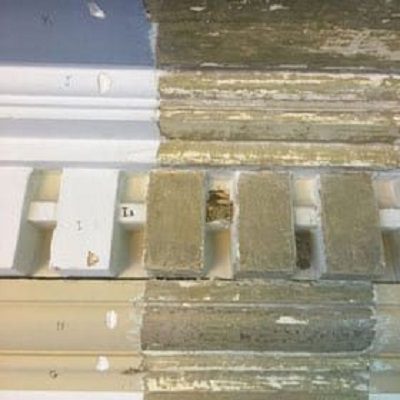

Prior to starting on the project, a conservator would typically run an adhesion test. The goal of this test is to determine areas of failure and their cause(s).

3. Establish The Key Requirements

The restoration needs to be done correctly, regardless of scale. It is important to define what qualifications you want a conservation expert to have. Any expert you consult with should meet the AIC code of ethics—a guideline for professional conduct within the conservation community.

There are additional standards that are material-specific but are crucial for long-term success. The nuances of applying different materials (interior/exterior gold leaf, Dutch metal, and copper leaf) can be vast, so it is paramount that the company you choose to work with has experience with both the medium you are applying and the surface it is being applied to. Remember, indoor and outdoor gold leaf applications require different standards, so make sure they have the right body of experience.

It is very important to obtain a second opinion. By comparing specifications from multiple conservation teams, you can compare their assessed scope, material selections, finishing techniques, and any pre-project scientific test. These pieces of information will give you a perspective of the kinds of skills needed in a conservator.

4. Obtain References

Obtaining references is an important step prior to selecting a conservation expert. Reviewing with past clients the not only the quality of the outcome, but also the restoration process can give you important perspective. Ensure that you consult past clients with project similar to yours—in this case, it would be important to review with clients who had gold leaf restored in a project commensurate in scale and situation to yours.

Additionally, try to obtain references from professional trade partners a perspective conservator has worked with—architects, contractors, and subcontractors. They should be able to provide sufficient references.