Real Gold Leaf

How to Choose?

There are two factors to consider in choosing gold leaf, its value and weight.

Gold Content

Gold content expresses the purity of the leaf and ranges from 6 karat to 24 karat which is 100% gold. The degree to which the gold is mixed with silver or bronze will determine the karat value-- silver will give a cooler tone and bronze a warmer tone. Gold content should be chosen in light of the project to be done, specifically whether the project is indoor or outdoor. All exterior projects should be gilded with gold leaf no less than 23.75 kt, since gold being the nobelist of metals is resistant to corrosion-- the purer it is, the stronger it will resist rain, snow, sleet, and wind. Gold leaf of such value will maintain its integrity for 30+ years. Interior projects, since they are not subject to climate changes, can be gilded with gold leaf of less than 23 kt. Typically, interior gilding of architectural features is 22 karat. The 21-22 karat is good for interiors and has been used for centuries because it is extremely durable. The gold leaf used for interiors if alloyed with other metals can actually make it more durable to withstand general wear and tear and cleaning.

An important note when it comes gilding and the size you use.

For architectural oil gilding, long size/slow drying size can only be used for exterior because of its elasticity that takes into consideration the changes of the climate conditions in the gilding process. Both the gold leaf and size will expand and contract with weather changes. If the quick/short size is used the gold leaf will be more brittle, less durable and not last as long. The wrong size being used could result in loss of the gold leaf integrity after one season vs the 30+ year when the correct gilding process is used. The long size/slow drying size can take days to harden and brittle which is what is required for exterior gilding.

Weight

Gold leaf is weighed in grams per 1,000 leaves. The heavier the gold leaf, the more resistant it is to the climate and environmental issues. For this reason, a substantially heavy leaf is required for all exterior gilding projects-- domes, statues, weathervanes, ornament. Typically, 18-23 grams per 1,000 leaves is recommended for exterior projects. As a studio, we will only use 21 or 23 grams. Interior gilding projects are considerably less vulnerable to climate and environmental issues and are therefore permitted to use a lighter leaf.

In conclusion, exterior projects require gold leaf with a certain value and weight while interior projects allow for more flexibility.

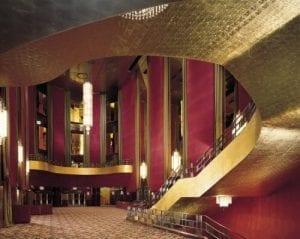

John Canning & Co. has used authentic gold leaf to execute a number of projects pictured here including the San Francisco City Hall, the West Virginia State Capitol, the Prometheus Statue at Rockefeller Center, the Horace Bushnell Memorial Theatre, the War Memorial Opera House, and many others.

Imitation Gold Leaf

Imitation leaf gives the appearance of solid gold despite the fact that it does not contain any gold at all. It is composed of some combination of copper, zinc, and brass and is much less expensive than gold leaf which is its primary drawing factor. Much like the low karat forms of authentic gold leaf, imitation gold can be more sensitive to climate and environmental issue and is therefore not recommended for exterior projects. It is often used indoors and its desirability comes from its inexpensive nature and the fact that it is easier to handle.