Fibrous Plaster Panels and Coffer Services

Using the HPCS products to stabilize and strengthen fibrous plaster panels.

Fibrous plaster molded panels, such as coffers, were mass-produced off site in thin lightweight panels that allowed for elaboration without the costs and skill required for traditional plaster. The panels were typically made in three basic steps.

- A pattern of varying degrees of complexity was created and from it a mold produced.

- Plaster was then brushed into the mold. The plaster was embedded with plant fibers to give it more strength.

- More plaster was brushed into the mold. The finished thickness of a cast plaster panel might be only ½.

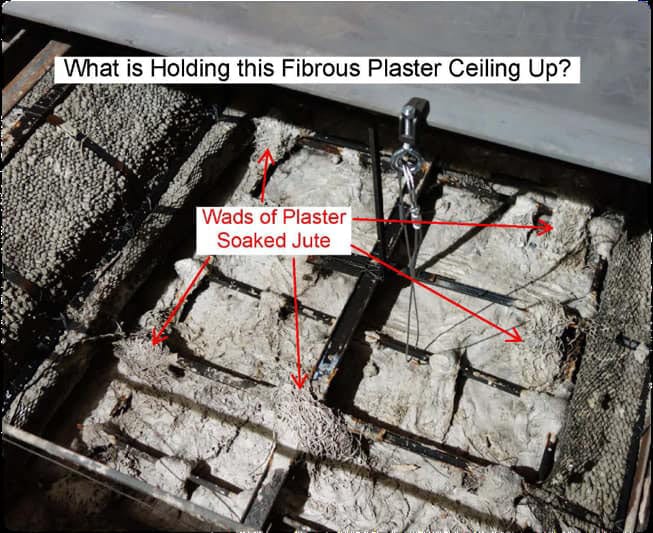

Typically, the panels were brought to the site, hung in place and tied with twine to a metal or wood frame. Wads of plaster, reinforced with a fiber such as jute, were then formed over the twin to connect the coffer panels to the metal or wood frames. The actual attachment of the ceiling panel therefore depends on the quality and condition of the jute and plaster of Paris that makes up these adhesive wads.

The main cause of problems with fibrous plaster ceiling panels is the breakdown of the natural fibers, which reinforce both the plaster panels and the wads of plaster that hold the panels in place. These fibers are subject to rot and desiccation. Inevitably, the building’s micro-movements cause the weakened panels to crack, disconnect and fall.

John Canning & Co. is an expert in stabilizing and reinforcing fibrous plaster ceiling panels and coffers. We use our extensive knowledge along with the HPCS treatment method to tackle these fibrous plaster stabilization and reinforcement projects.

John Canning & Co. uses a HPCS product called RE Aramid Gel ™, specifically designed to stabilize and strengthen fibrous plaster panels. It is ideal for establishing new structural support hooks without causing surface damage.

Independent testing confirmed RE Aramid Gel™ provides the tensile and structural adhesion strength required for long-lasting plaster reinforcement, and the flexibility to withstand a building’s micro-movement and prevent cracking.

Testimonials

"Architects know that Canning will only do the finest work possible. "

-DUNCAN G. STROIK,AIA, PRINCIPAL DUNCAN G. STROIK ARCHITECT, SOUTH BEND, INDIANA-

"Canning has brought an outstanding common sense attitude of accomplishment to their work when many others are lost within myriad complex issues."

-RUTHANN HUBBARD-KEMPER, EXECUTIVE DIRECTOR, PENNSYLVANIA CAPITOL PRESERVATION COMMITTEE, HARRISBURG, PENNSYLVANIA

Here is a short video showing the HPCS process of the treatment of fibrous plaster.

Our Process

Often a plaster survey/assessment of the fibrous panels/coffers is required to determine the extent of the problems.

We assess the structural integrity of the plaster system and compare it’s current condition to its “as-built” condition to determine where the plaster system is in its “service life”

- Dissect one or more of the plaster & natural fiber (jute) wads that connect the panels to the armature.

- Determine if natural fibers are desiccated (dry rotted).

- If fibers are desiccated, connections need to be reinforced.

- If panels are cracking and natural fibers are desiccated, then panels also need to be reinforced.

The typical treatment process of the fibrous plaster panels/coffers:

- Apply diluted formulation of acrylic resin to back of panel/coffer. The resin will fill cracks and strengthen the matrix of the panels.

- If relatively small area requires treatment, hand-brush apply an acrylic gel mixed with polyester fibres (i.e. Kevlar) to the back of each panel.

- If larger area requires treatment, spray apply the acrylic gel mixed with polyester fibers to the back of each panel.

- This treatment program will strengthen the fibrous plaster panels and reinforce each panel’s connection to the metal or wood armature.

Cost Factors

The exact cost of stabilization & reinforcement of fibrous plaster panels/coffers naturally depends on a number of factors. These include, but are not limited to:

Whether or not the process begins with a plaster conditions survey/assessment

- The size of the work

- The complexity of the work

- The location of the work, and required access (for example, whether or not scaffolding will be required to access the space)

- Special materials cost, such as consolidants, adhesives, etc.

For this reason, it is difficult to say what the “typical” cost for stabilization & reinforcement of fibrous plaster panels/coffers may be. The surest way to get an accurate idea of what costs your project may entail is to contact us directly.

Our Specialties

In addition to consolidation of plaster on wood lath , we specialize in a number of other complementary services, including: