Gilding is the decorative process of applying a layer of metal to a certain surface in order to provide it with a unique beauty and richness. This is done using very thin sheets of the desired metal called leaf, which, when applied to a surface using adhesive, gives the appearance of solid gold, silver, copper or whatever metal leaf is used. The astounding effect of gilding is so enticing that it has been an element of decoration since the 23rd century BC. Certain forms of gilding date back to as early as ancient Egypt, having been found integrated into paintings from Egyptian tombs.

Process

The art of gilding requires delicacy, precision, and attention as metal leaf is very thin and must be handled with care. There are five basic steps to the gilding process.

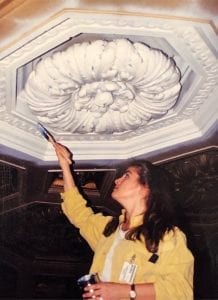

The Gilding Process (Work Being Performed at the San Francisco Opera House on the Grand Lobby Ceiling)

1) Prepare the Surface

Make sure the surface intended to be gilded is clean and free of damage. This cannot be overemphasized. A light sanding will often help smooth the surface. Primer is applied in order to give the surface a uniform color, or to set a desired undertone for the leaf. Warm colors like red are used to give a warm, rich effect to the end product while blue and gray tones are used to give a cooler undertone. Prior to any applications of primer, finish coat of paint or the application of adhesive, the surface must be cleaned with a solvent, such as mineral spirits to remove any grease, dust or other contaminants that may adversely affect that coat system.

2) Apply Adhesive

The adhesive used to secure the metal leaf is called gilding “size” and can be water based or the traditional oil based. Water-based size should never be used for exterior gilding projects since it is subject to damage when exposed to moisture. For interior projects, either size may be used. Water-based gilding is more labor intensive but often achieves a more refined appearance and is therefore commonly used on projects handled at more intimate distanced such as picture frames or furniture. The oil size is the equivalent of a slow drying oil varnish. As it dries, the oil film becomes tacky, but not wet. This sweet spot is the point when the leaf should be applied and is called the ‘tack.’

3) Apply Leaf

Sheets of the desired metal leaf come in either loose leaf form or attached to wax paper which allows for precise transfer of the metal to the tacky size.

4) Remove Excess

Due to the fragility of the leaf, the excess lining the overlap of leaves can be removed easily using a soft brush, such as sable hair, or cloth, such as velvet.

5) Seal and Finish

Composite leaf such as dutch metal, are usually sealed with a protective coating (varnish/sealer) after being applied to the adhesive in order to preserve the metal and keep it from tarnishing. Other metals such as silver, copper, aluminum, and palladium typically do not require a protective coating. Genuine gold leaf, does not require a protective coating.

San Francisco Opera House – Grand Lobby Ceiling Gilding Completed

The scope for the San Francisco War Memorial Opera House restoration project included re-gilding the foyer, the auditorium, the proscenium, the mezzanine boxes and all interior architectural elements throughout the Opera House.

Purpose of Gold Leaf

Of all gilding types, gold leaf is the most common material employed. Gold is a noble metal. It is magnificent to behold in its beauty, boldness, and shine. Representing power and wealth due to its expensive nature, gold is often used in political buildings and expensive homes. Gold has also been used for hundreds of years to represent nobility, divinity, and anything worthy of respect. Gold has a power to elevate the mind to higher things. For this reason, gold leaf has been especially used throughout history in the decoration of religious buildings both exteriorly and interiorly.

Radio City Music Hall Lobby, NYC

John Canning & Co. restored many elements of Radio City Music Hall to their original 1932 gilded finishes which included aluminum leaf, Dutch metal leaf, copper leaf, and gold leaf. The project covered over 90,000 square feet of surfaces throughout the building including the Grand Foyer, the Orchestra Level, the Mezzanine Levels, the Smoker’s Lounge, and the Basement.

Gilded Promethius Statue

The re-gilding of the 18-foot Prometheus Statue located at Rockefeller Center in New York City was accomplished by the company using authentic gold leaf

Shrine of Our Lady of Guadalupe Gilding in progress.

John Canning & Co. was intimately involved in the design and beautification of the Shrine of Our Lady of Guadalupe in La Crosse, WI. One of many jobs performed was the gold leaf gilding of the constellations in the brilliant turquoise dome ceiling of the church. The capitols and canopy with the seraphim’s were also faux finished to simulate aged gilded bronze, and marbled.

San Francisco City Hall Gold Leaf Dome

Exterior gilding was performed by John Canning & Co. on the dome of San Francisco City Hall using traditional gold leaf. This dome rates tallest in the US, extending 361 feet, and is considered a National Historic Landmark.

Choosing Gold Leaf

Gold leaf varies with weight and gold content. Gold content expresses the purity of the leaf and ranges from 6 karat to 24 karat which is 100% gold. The degree to which the gold is mixed with silver or bronze will determine the karat value– silver will give a cooler gold tone and bronze a warmer tone. Gold is resistant to corrosion which is why, as a general rule, 23kt or more should be used for exterior gilding. In addition, gold leaf of 23kt or more will maintain its integrity for more than 30 years. The other factor to consider in choosing gold leaf is its weight. Like purity, the heavier the leaf the more resistant it is to corrosion. Gold leaf is weighed in grams per 1,000 leaves. Exterior gilding requires heavier leaf– typically 18-23 grams per 1,000 leaves. Interior gilding allows for a wider range of weight and may use a lighter leaf.

St. Panteleimon Church Gilding in Process

John Canning & Co. renewed six exterior domes and their crosses at St. Panteleimon Church in Hartford, CT. The weathered gold was stripped, primed, and regilded with 23.75 kt gold leaf for a durable and long lasting effect.

St. Panteleimon Church Gilding Complete

Why Use the Real Thing? Authentic Gold Leaf vs. Imitation Gold Leaf

Imitation gold leaf, also referred to as Composition Gold Leaf, Dutch Metal, or Dutch Gold is made from a combination of copper, zinc, and brass. While imitation leaf is less expensive and helpful for certain projects, it is usually more beneficial to use authentic gold leaf for both appearance and durability. The aesthetic of authentic gold leaf is much more consistent, rich, and brilliant than imitation leaf. Imitation leaf can be uneven in its pigment distribution and give subtle appearances of streaks if an imitation paint is used. Authentic leaf is also more practical since it will maintain its integrity for many years. Imitation leaf is subject to oxidation and tarnish and, even if sealed with a protective top coat, it will often not last more than a few years without acquiring a green, dull haze. Circumstances aside, using authentic gold leaf for a gilding project is usually worth the investment.

Gilding in Process

Cost

The factors that play a role in determining the cost of a certain gilding project depend on a number of unique circumstances. For this reason, it is hard to state what a typical cost might be. Some basic cost factors include the following:

- The type of metal leaf to be used (whether gold, silver, or some other metal)

- The size, complexity, and scope of the project

- Required access (for example, whether the surface is located on a wall vs. a ceiling vs. an exterior surface like a dome)

- Whether the underlying structure must be repaired, stabilized, or restored

- Special materials costs

-

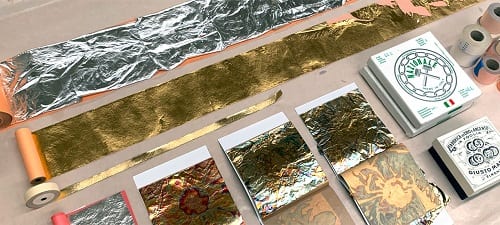

Gilding Leaf Samples

Gilding, when performed well, is a very useful tool in decoration. It can elevate any material to a new status-to resemble something rich, noble, or even divine. It is therefore beneficial to know the essential elements that constitute the gilding process in order to properly convey whatever meaning might be intended.

If you have a gilding project you would like to discuss, contact us.